Tympanum genus machinae lignum chipper pro ramis et lignis

Zhangsheng Drum chipper traditum productum est, quod late a mercatoribus domesticis et exteris per multos annos adhibitum est propter superioris operis effectum, qualitatem altam et sumptus effectus.

Silva de portu pascendo pascitur.Cum lignum incidat cum falce secet, alta celeritate rotatione falcis secabitur.Mechanismus secans est tympanum rotatum in quo plures cultri volantes installantur, et cultri volans rotantur.In lignum eu lignum discursum est.Plures quadrati sunt per foramina in margine exteriore rotae tympani, et frusta qualificata incisa cadunt per foramina reticulata et emittuntur ad imum, et iterum in machina secabitur frusta magna.

Tympanum TITIO componitur ex corpore, cultro cylindro, superiori et inferiore mechanismum pascendi, systema hydraulicum, fabrica pascendi et alias partes.

1. Corpus: in altum robur laminae ferreae iuncta est, basis totius machinae fulcrum est.

2. Cultrum cylindrus: Duo vel tres vel quatuor cultri volantes in baculo cultelli inponuntur, et cultri volans in cylindro cultro figuntur per truncum pressionis cum specialiter fabricatis volatilibus cultellis.

3. Ratio hydraulica: Oleum sentinam ad cylindrum oleum praebetur, et operculum ad faciliorem laminae reponendam excitari potest;durante sustentatione, superior pastio cylindrus conventus elevari potest, accommodare gap inter cultrum volatum et fundum cultellum et disassemblionem et ecclesiam pectinis laminam.

4. Mechanismum pascendi superiorem et inferiorem: Componitur pascendi interfacies, superiores et inferiores bracchiis pascens et mechanismum intermedium pascens temperatio.Silva e pastu ingrediens scutulis alendis superioribus et inferioribus premitur, et certa mechanismo secante certa celeritate pascitur.Moles ligni secantis astuli;cum lignum densum dispensando, a pastu gap commensuratio mechanism accommodatur.

| Model | 216 | 218 | 2110 | 2113 |

| Capacitas(t/h) | 5~8 | 10~12 | 15~18 | 20~30 |

| Pondus (kg) | 5.5 | 8 | 15 | 18 |

| Ratio (m) | 2.2×1.8×1.23 | 2.5×2.2×1.5 | 2.85×2.8×1.8 | 3.7×2.5×2.1 |

| Longitudo (mm) | 560×250 | 700×350 | 1050×350 | 700×400 |

| Motor (kw) | 55 | 110 | 132~ 160 | 200~250 |

| Diesel(hp) | 80 | 160 | 280 | 380 |

| Outlet Size (mm) | 30~80 | 30~80 | 30~80 | 30~80 |

| Crassitudo (mm) | 2-3 | 2-3 | 2-3 | 2-3 |

Q1: Quid modi mercedem accipitis?

Variis modis solutionem sustinemus, depositum accipere possumus XX% vel XXX%.lf reditus est, C% solutionem per exemplum accipere possumus B/L.solucionis methodflexible.

Q2: Quousque partus est tempus?

Plus quam 1500 metra quadrata habemus in officina inventarii maculae, et plerumque 5-10days pro bonis sufficienti inventario sumit.If you need to customize the equipment, takes 20-30days.Optimum erimus ut quam primum tradamus.

Q3: Quid si machina corrumpitur?

Uno anno warantizatio et comprehensio post venditionesque servitii. Post hanc periodum, inferiorem feodum conservare post-venditionem servitii dabimus.

Q4: Ubi est forum productum et ubi est forum commodum?

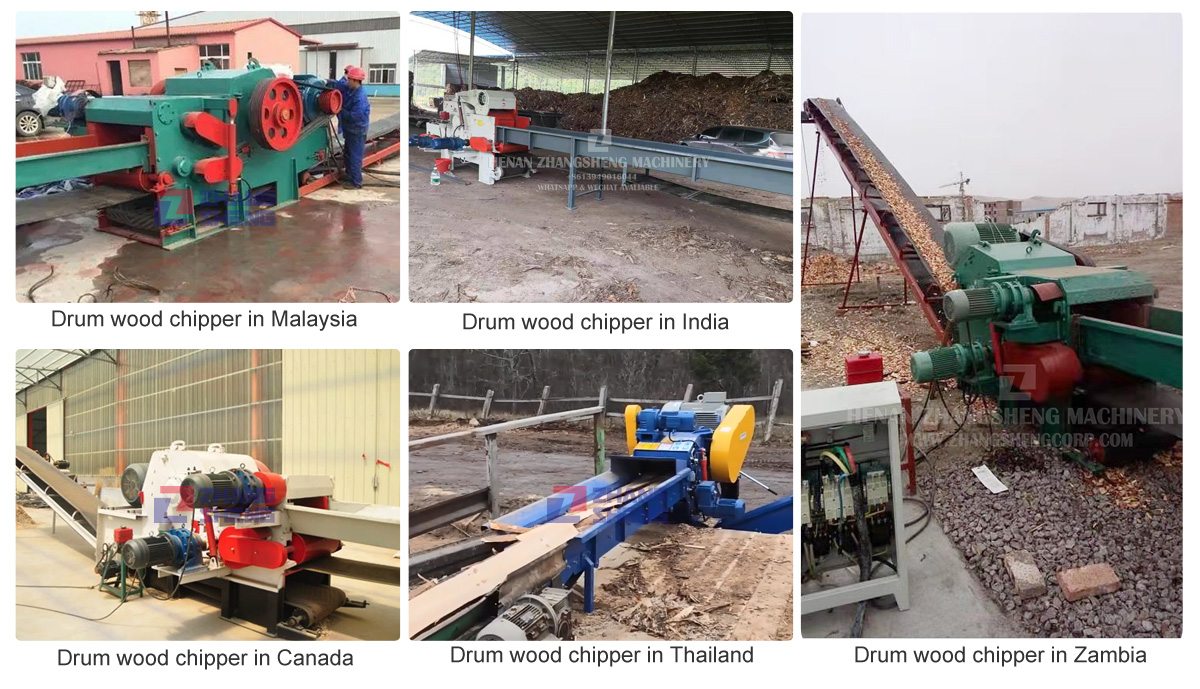

Forum nostrum totum Orientem Medium et Europae et Americanorum regiones tegit, et exportationes ad plusquam 34 regiones sunt.In MMXIX, domestica venditio RMB XXIII decies centena excessit.Valor exportationis ad 12 decies centena milia dollariorum pervenit.Praeterea, venditiones tres annos continuos creverunt.Productum qualitas et novum productum investigationis et evolutionis facultates Zhangsheng Machinery fide tua digna sunt.Et perfectus TUV-CE certificatorium et certa pre-venditio et post-venditio servitii sunt quod laboramus ad faciendum.